ASP 710 and 800

A cooling tower is a device that is designed to transfer heat from the specific manufacturing process of the atmosphere by the means of heat dissipation evaporative by lowering the temperature of the circulating water.

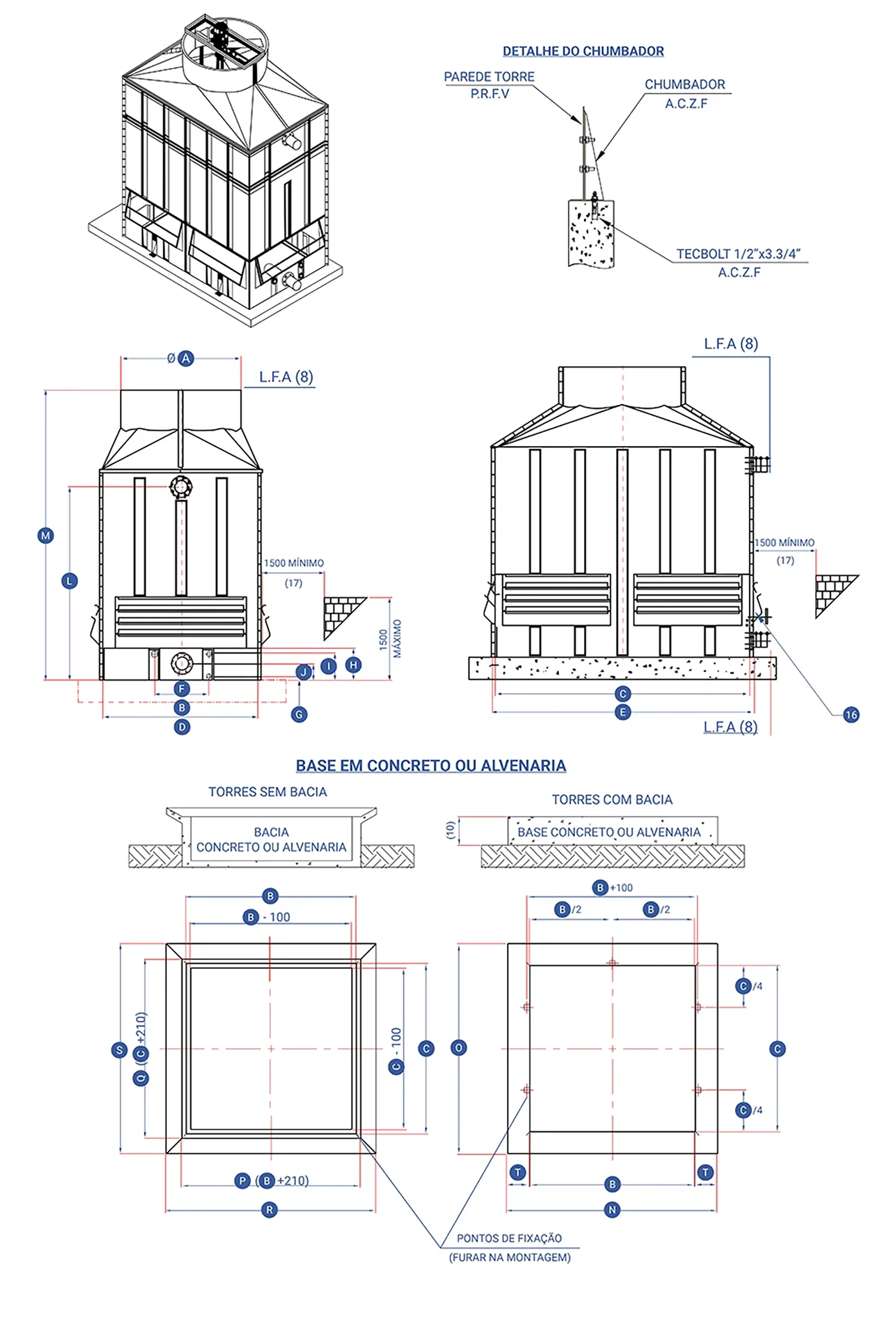

All models FUTURE ASPIRATION) 710 800with a circulation of air being sucked into the current of the water, and have a vent in a way that is induced, that is, from the inside to the outside, with funding from the air, the landscape, and the discharge of the air in the vertical upward movement through the axial fan with low power consumption. Manufactured in GRP (Polyester Reinforced with Fiber Glass), are characterized by a high resistance to corrosion and they are designed in a variety of sizes, it can also be the most compact for fitting in tight spaces, to be deployed semimontadas, it also removes the need for the provision of services for the assembly and installation in the field, that is, the plug-in to play.

Get in touch with the team at the ALFATERM and schedule a service visit from one of our experienced engineers!

ASP 710

| Model | ASP 710 | ||

|---|---|---|---|

| A | 1600 | ||

| B | 2050 | ||

| C | 3420 | ||

| D | 2170 | ||

| E | 3540 | ||

| F | 730 | ||

| G | 50 | ||

| H | 430 | ||

| I | 350 | ||

| J | 180 | ||

| L | |||

| Number of layers of filler | |||

| 2 | 2550 | ||

| 3 | |||

| 4 | 3330 | ||

| 5 | |||

| M | |||

| Number of layers of filler | |||

| 2 | 3900 | ||

| 3 | |||

| 4 | 4760 | ||

| 5 | |||

| N | 2550 | ||

| O | 3920 | ||

| P | 2260 | ||

| Q | 3630 | ||

| R | 3140 | ||

| S | 4300 | ||

| T | 250 | ||

| Connections | |||

| V | 1" | ||

| W | 2" | ||

| X | 6" | ||

| Y | 8" | ||

| Z | 1.1/2" | ||

| The Volume of the water in the bowl | (L) | 2380 | |

| with the fan weight (KG) | Emb. | 1650 | |

| Oper. | 4320 | ||

| 01. | THE CONNECTION TO THE V = DRAIN, THREADED BSP | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 02. | CONNECT W OVERFLOW, THE THREAD BSP | ||||||||||||||||

| 03. | THE CONNECTION TO THE X = THE ENTRANCE TO THE HOT WATER THROUGH THE HOSE AND RUBBER | ||||||||||||||||

| 04. | THE CONNECTION OF THE Y = OUTPUT OF COLD WATER THROUGH THE HOSE AND RUBBER | ||||||||||||||||

| 05. | CONNECTION TO Z-THE ENTRANCE TO THE WATER OF A REPLACEMENT, FAUCET SINGLE) | ||||||||||||||||

| 06. | CONNECTIONS TO THE INLET AND THE OUTLET OF THE WATER THROUGH THE HOSE AND RUBBER | ||||||||||||||||

| 07. | DIMENSIONS ARE IN MILLIMETERS (INCHES) | ||||||||||||||||

| 08. | L. F. A. = MAXIMUM SUPPLY ALFATERM | ||||||||||||||||

| 09. | PROVIDE SUPPORT TO THE PIPING | ||||||||||||||||

| 10. | THE CONSTRUCTION OF THE SUPPORT BASE OF THE TOWER IS EXPECTED TO BE IN THE CONCRETE / MASONRY, FLAT, LEVEL AND OF THE RESPONSIBILITY OF THE CUSTOMER | ||||||||||||||||

| 11. | ANY OBSTACLE IN THE VICINITY OF THE TOWER, YOU MUST HAVE THE APPROVAL OF THE ALFATERM | ||||||||||||||||

| 12. | THE PRESSURE REQUIRED AT THE INLET OF THE DOMESTIC HOT WATER, ACCORDING TO THE DATA SHEET | ||||||||||||||||

| 13. | 'COLOR' = - FILLING-TYPE BLOCKS AND BARS IN THE SHAPE OF THE WAVES CROSSED, POLYPROPYLENE, POLYPROPYLENE, ANTI-FLAME, V-0 OR POLYPROPYLENE, ANTI-FLAME AND V-2 | ||||||||||||||||

| 14. | 'BUS RAPID TRANSIT'=, FILLING TYPE, THE BARS OF A DROP-TUBE, POLYPROPYLENE, POLYPROPYLENE, ANTI-FLAME, V-0 OR POLYPROPYLENE, ANTI-FLAME AND V-2 | ||||||||||||||||

| 15. | 'PUT'=, FILLING TYPE, BLOCKS, FILM, PVC, | ||||||||||||||||

| 16. | TROUGH SINK FOR DROP, BUILT-IN | ||||||||||||||||

| 17. | OBSERVE THE MINIMUM DISTANCE AND A MAXIMUM HEIGHT OF 1500 MM FOR WALLS AND OBSTACLES | ||||||||||||||||

| 18. | SUBJECT TO CHANGE WITHOUT NOTICE PRIOR | ||||||||||||||||

| An example of a specification |

|

ASP 800

| Model | ASP 800 | ||

|---|---|---|---|

| A | 1600 | ||

| B | 2050 | ||

| C | 3990 | ||

| D | 2170 | ||

| E | 4110 | ||

| F | 730 | ||

| G | 50 | ||

| H | 430 | ||

| I | 350 | ||

| J | 180 | ||

| L | |||

| Number of layers of filler | |||

| 2 | 2550 | ||

| 3 | |||

| 4 | 3300 | ||

| 5 | |||

| M | |||

| Number of layers of filler | |||

| 2 | 3900 | ||

| 3 | |||

| 4 | 4760 | ||

| 5 | |||

| N | 2550 | ||

| O | 4490 | ||

| P | 2260 | ||

| Q | 4200 | ||

| R | 3140 | ||

| S | 4870 | ||

| T | 250 | ||

| Connections | |||

| V | 1" | ||

| W | 2" | ||

| X | 6" | ||

| Y | 8" | ||

| Z | 1.1/2" | ||

| The Volume of the water in the bowl | (L) | 2800 | |

| with the fan weight (KG) | Emb. | 1820 | |

| Oper. | 4950 | ||

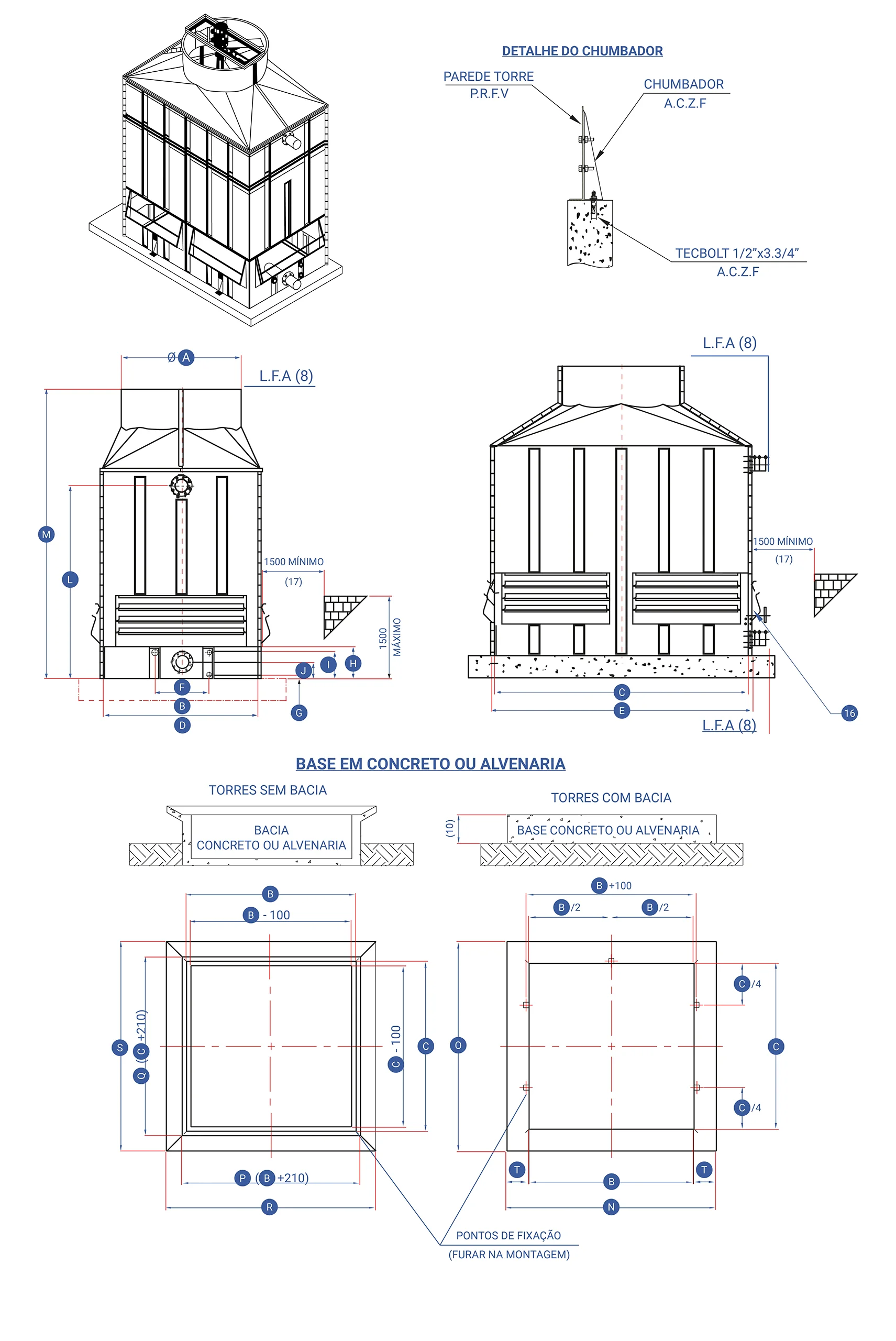

| 01. | THE CONNECTION TO THE V = DRAIN, THREADED BSP | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 02. | CONNECT W OVERFLOW, THE THREAD BSP | ||||||||||||||||

| 03. | THE CONNECTION TO THE X = THE ENTRANCE TO THE HOT WATER THROUGH THE HOSE AND RUBBER | ||||||||||||||||

| 04. | THE CONNECTION OF THE Y = OUTPUT OF COLD WATER THROUGH THE HOSE AND RUBBER | ||||||||||||||||

| 05. | CONNECTION TO Z-THE ENTRANCE TO THE WATER OF A REPLACEMENT, FAUCET SINGLE) | ||||||||||||||||

| 06. | CONNECTIONS TO THE INLET AND THE OUTLET OF THE WATER THROUGH THE HOSE AND RUBBER | ||||||||||||||||

| 07. | DIMENSIONS ARE IN MILLIMETERS (INCHES) | ||||||||||||||||

| 08. | L. F. A. = MAXIMUM SUPPLY ALFATERM | ||||||||||||||||

| 09. | PROVIDE SUPPORT TO THE PIPING | ||||||||||||||||

| 10. | THE CONSTRUCTION OF THE SUPPORT BASE OF THE TOWER IS EXPECTED TO BE IN THE CONCRETE / MASONRY, FLAT, LEVEL AND OF THE RESPONSIBILITY OF THE CUSTOMER | ||||||||||||||||

| 11. | ANY OBSTACLE IN THE VICINITY OF THE TOWER, YOU MUST HAVE THE APPROVAL OF THE ALFATERM | ||||||||||||||||

| 12. | THE PRESSURE REQUIRED AT THE INLET OF THE DOMESTIC HOT WATER, ACCORDING TO THE DATA SHEET | ||||||||||||||||

| 13. | 'COLOR' = - FILLING-TYPE BLOCKS AND BARS IN THE SHAPE OF THE WAVES CROSSED, POLYPROPYLENE, POLYPROPYLENE, ANTI-FLAME, V-0 OR POLYPROPYLENE, ANTI-FLAME AND V-2 | ||||||||||||||||

| 14. | 'BUS RAPID TRANSIT'=, FILLING TYPE, THE BARS OF A DROP-TUBE, POLYPROPYLENE, POLYPROPYLENE, ANTI-FLAME, V-0 OR POLYPROPYLENE, ANTI-FLAME AND V-2 | ||||||||||||||||

| 15. | 'PUT'=, FILLING TYPE, BLOCKS, FILM, PVC, | ||||||||||||||||

| 16. | TROUGH SINK FOR DROP, BUILT-IN | ||||||||||||||||

| 17. | OBSERVE THE MINIMUM DISTANCE AND A MAXIMUM HEIGHT OF 1500 MM FOR WALLS AND OBSTACLES | ||||||||||||||||

| 18. | SUBJECT TO CHANGE WITHOUT NOTICE PRIOR | ||||||||||||||||

| An example of a specification |

|